Introduction: From Guesswork to Precision

In today’s fast-paced logistics environment, managing demand accurately is critical for business success. A single miscalculation can lead to stockouts, overstocking, or costly disruptions across the supply chain. Traditional forecasting methods-often dependent on historical data and static models-can’t keep up with modern market complexities.

This is where AI Demand Forecasting in Logistics is transforming the game. By harnessing artificial intelligence (AI) and machine learning (ML), businesses can now predict customer demand with unprecedented accuracy, optimize inventory levels, and eliminate uncertainty from supply chain planning.

Why Traditional Forecasting Falls Short

For years, businesses have relied on spreadsheets and basic statistical models to forecast demand. While these methods worked in the past, they fail to handle today’s dynamic logistics landscape influenced by fluctuating consumer preferences, global disruptions, and real-time supply variables.

Challenges with Traditional Forecasting

- Static Data Models: Unable to adapt to changing market trends or unforeseen disruptions.

- Human Error: Manual forecasting often introduces inaccuracies and bias.

- Delayed Response: Lack of real-time visibility prevents quick course correction.

Traditional forecasting focuses on what has happened, while AI forecasting predicts what will happen next.

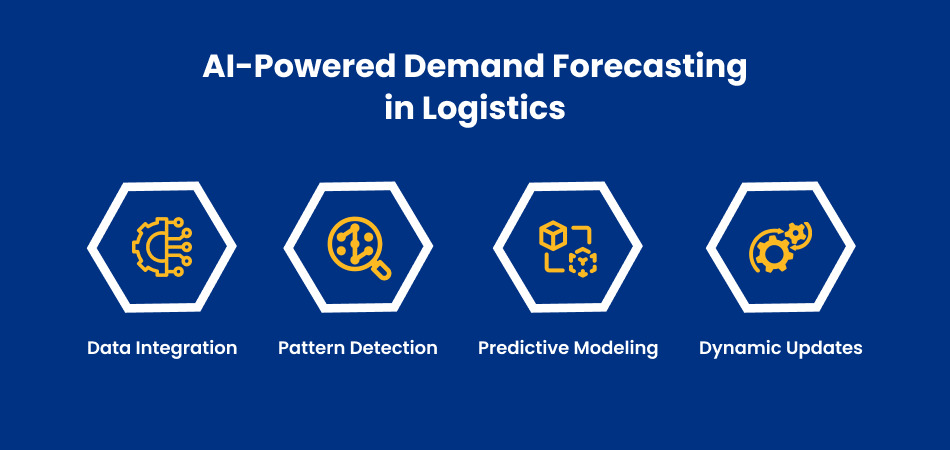

How AI Demand Forecasting Works in Logistics

AI Demand Forecasting in Logistics uses data-driven algorithms to continuously learn from real-world events and deliver accurate, actionable insights. Instead of relying on one-dimensional data, it integrates multiple data points to produce holistic forecasts.

Step-by-Step Process

- Data Integration

AI aggregates data from diverse sources-including ERP systems, POS transactions, supplier networks, weather reports, and even social media trends. - Pattern Detection

Machine learning models identify hidden correlations between demand, geography, seasonality, and external factors. - Predictive Modeling

Advanced AI algorithms use this data to forecast demand with high precision. - Dynamic Updates

As new data flows in, AI models automatically adjust forecasts, ensuring ongoing accuracy.

With AI-driven insights, logistics managers can anticipate demand surges, optimize procurement, and reduce inventory costs.

Key Benefits of AI Demand Forecasting in Logistics

1. Eliminate Stockouts and Overstocking

AI ensures the right products are available at the right time, reducing lost sales and preventing costly overstocking.

2. Optimize Operational Costs

By maintaining balanced inventory levels, businesses can cut storage expenses and minimize waste.

3. Improve Customer Satisfaction

Accurate forecasts mean timely deliveries and consistent product availability-resulting in happier, more loyal customers.

4. Enable Real-Time Decision-Making

AI forecasting tools process real-time data, empowering logistics teams to make quick and informed decisions.

5. Strengthen Supply Chain Visibility

AI-driven platforms provide end-to-end transparency across suppliers, warehouses, and distribution networks.

Real-World Use Cases of AI Demand Forecasting

Retail and E-commerce

Predicting peak-season demand, adjusting stock distribution, and minimizing delivery delays.

Manufacturing

Ensuring timely availability of raw materials and optimizing production cycles.

Pharmaceuticals

Maintaining a consistent supply of critical medications without overproduction or waste.

Food and Beverage

Forecasting demand based on seasonality and market trends to reduce spoilage and loss.

Companies adopting AI Demand Forecasting in Logistics have reported:

- Up to 40% reduction in stockouts

- 30–35% lower inventory costs

- 25% faster order fulfillment rates

Implementing AI Forecasting in Your Supply Chain

1. Data Assessment

Evaluate and clean existing data from sales, suppliers, and operations to ensure accuracy.

2. Select an AI Platform

Choose scalable, cloud-based AI tools that integrate seamlessly with ERP, CRM, or warehouse systems.

3. Pilot Testing

Start with one product line or region to measure performance before scaling company-wide.

4. Continuous Model Training

Feed new data into the system regularly to enhance forecasting precision over time.

5. Scale and Automate

Once results are validated, expand the AI forecasting model across your entire supply chain network.

The Future of AI in Demand Forecasting

The evolution of AI Demand Forecasting in Logistics will soon merge with technologies like the Internet of Things (IoT), blockchain, and real-time analytics. This will enable autonomous, self-optimizing supply chains capable of predicting and responding to changes instantly.

In the coming years, businesses can expect:

- Cognitive Supply Chains: Systems that self-learn and adjust in real time.

- AI-Driven Sustainability: Reducing waste and carbon footprints through efficient resource planning.

- Deeper Integration: Seamless collaboration between suppliers, logistics providers, and distributors.

Organizations that adopt AI now will lead in efficiency, agility, and customer experience — gaining a powerful competitive edge.

Conclusion: The End of Guesswork in Supply Chains

Stockouts are no longer an unavoidable challenge. With AI Demand Forecasting in Logistics, businesses can move from reactive problem-solving to proactive, data-driven planning.

AI empowers companies to forecast with confidence, optimize operations, and enhance customer satisfaction-making the entire supply chain leaner, smarter, and more resilient.

Key Takeaway

AI transforms demand forecasting from an estimate into an exact science.

With AI Demand Forecasting in Logistics, your supply chain gains the intelligence to predict trends, prevent losses, and deliver the right products-every time, on time.

Frequently Asked Questions (FAQs)

1. What is AI Demand Forecasting in Logistics?

AI Demand Forecasting in Logistics uses artificial intelligence and machine learning to analyze data from various sources and predict product demand accurately. This helps logistics and supply chain managers plan inventory, reduce costs, and avoid stockouts.

2. How does AI improve traditional demand forecasting methods?

Unlike traditional models that rely solely on past data, AI incorporates real-time information -such as customer behavior, weather patterns, and market trends — to make forecasts more adaptive and precise.

3. What types of data does AI use for demand forecasting?

AI systems use sales records, supplier data, customer purchase history, economic trends, seasonal cycles, and even external factors like social sentiment and weather conditions.

4. Can small and mid-sized businesses use AI forecasting tools?

Yes. Cloud-based AI platforms make implementation affordable and scalable, allowing even small logistics companies to benefit from predictive forecasting capabilities.

5. What are the key benefits of implementing AI in logistics forecasting?

- Reduced stockouts and overstocking

- Improved cost efficiency

- Better supply chain visibility

- Enhanced customer satisfaction

- Real-time adaptability to market shifts

6. What’s the future of AI in logistics demand forecasting?

Future AI forecasting models will integrate with IoT sensors, blockchain, and automation to create real-time, self-learning supply chains capable of predicting and adjusting operations automatically.

Final Thought:

AI-powered forecasting isn’t just about predicting demand-it’s about transforming how logistics companies plan, operate, and grow. With AI Demand Forecasting in Logistics, the future of supply chain management is smarter, faster, and more reliable than ever before.