Introduction: The AI-Powered Logistics Revolution

The logistics industry is undergoing a transformation unlike any seen before. Artificial Intelligence (AI) has become the driving force behind smarter decision-making, greater accuracy, and leaner operations. No longer a futuristic concept, AI is now at the heart of modern logistics — optimizing delivery routes, forecasting demand, maintaining fleets, automating warehouses, and mitigating supply chain risks.

In this complete guide, we’ll explore how AI is revolutionizing every layer of logistics — from real-time delivery optimization to predictive analytics — and how your business can leverage these innovations for efficiency and cost savings.

Why Logistics Needs AI More Than Ever

The global logistics ecosystem is more complex than ever. Volatile fuel prices, shifting consumer demands, and supply chain disruptions have forced logistics providers to evolve. Traditional systems can no longer keep up with the unpredictable nature of global trade and real-time customer expectations.

AI bridges this gap by transforming data into actionable insights. It empowers businesses to make intelligent decisions based on real-time information — improving visibility, reducing waste, and maximizing efficiency. Whether it’s rerouting a delivery truck due to traffic or predicting inventory needs before shortages occur, AI ensures logistics operations remain agile and resilient.

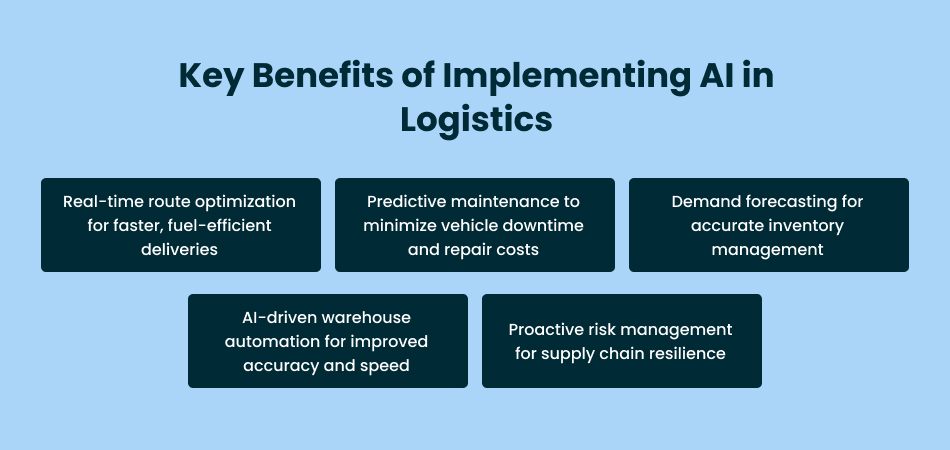

Key Benefits of Implementing AI in Logistics

Artificial Intelligence is not just an add-on — it’s a fundamental enabler of operational excellence. Here are the core benefits businesses experience when integrating AI across logistics workflows:

- Real-time route optimization for faster, fuel-efficient deliveries

- Predictive maintenance to minimize vehicle downtime and repair costs

- Demand forecasting for accurate inventory management

- AI-driven warehouse automation for improved accuracy and speed

- Proactive risk management for supply chain resilience

Smarter Route Optimization with AI: Redefining Delivery Efficiency

One of the biggest operational challenges in logistics is ensuring on-time delivery while controlling costs. AI-powered route optimization systems analyze live traffic, weather conditions, and vehicle data to identify the most efficient delivery paths — instantly adapting to changes in real time.

With AI, logistics firms can achieve up to 30% lower fuel consumption and 20% faster delivery times. The technology goes beyond simple GPS mapping — it learns from patterns, predicts potential delays, and continuously improves routing decisions.

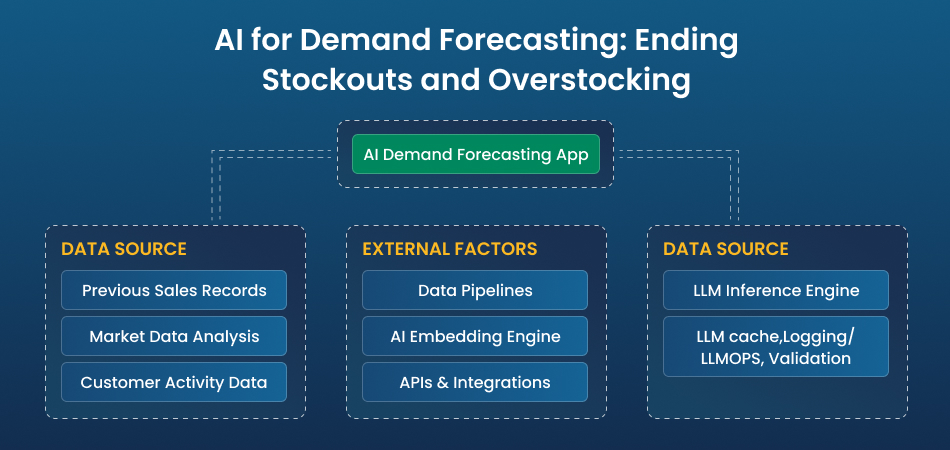

AI for Demand Forecasting: Ending Stockouts and Overstocking

Traditional demand forecasting methods often rely on static historical data — making them ineffective during rapid market shifts. AI-driven demand forecasting in logistics leverages big data, machine learning, and predictive analytics to identify future demand with remarkable precision.

By analyzing sales trends, seasonality, and external market signals, AI enables logistics teams to maintain the perfect balance between supply and demand. This not only reduces storage costs but also prevents costly stockouts.

Companies using AI-powered forecasting have reported up to 35% reductions in inventory costs and improved order fulfillment rates.

Predictive Maintenance: Keeping Fleets Running Smoothly

Unplanned vehicle breakdowns can severely disrupt the logistics chain. AI-based predictive maintenance systems analyze vehicle data — such as vibration, fuel efficiency, and engine temperature — to predict when a failure is likely to occur.

Instead of waiting for breakdowns, logistics operators can perform maintenance proactively, minimizing downtime and repair costs. This AI-driven approach extends vehicle lifespan, improves reliability, and helps maintain consistent service levels.

AI-Driven Warehouse Automation: The Future of Order Fulfillment

Warehouses are no longer just storage spaces — they’re smart hubs of innovation. Through AI warehouse automation, companies are deploying robots, computer vision systems, and machine learning algorithms to handle everything from inventory sorting to order packing.

AI ensures every square foot of warehouse space is utilized effectively while minimizing human error. It also improves labor efficiency and speeds up fulfillment, leading to enhanced customer satisfaction.

From robotic pickers to smart conveyors and intelligent shelf scanning, the AI-driven warehouse ecosystem operates 24/7 with near-perfect accuracy.

Boosting Resilience with AI-Powered Supply Chain Risk Management

Global supply chains face constant disruptions — natural disasters, geopolitical events, or supplier instability. AI helps logistics companies anticipate and mitigate risks in real time.

By monitoring external data sources — like weather forecasts, political developments, and shipping routes — AI systems can detect potential disruptions before they escalate. These insights allow logistics teams to take corrective action early, ensuring business continuity.

AI not only identifies risks but also suggests optimal responses, making supply chains more adaptive and resilient.

How AI Enhances Sustainability in Logistics

Sustainability is a growing priority for logistics providers worldwide. AI plays a critical role in reducing carbon footprints by improving fuel efficiency, optimizing routes, and minimizing waste.

AI systems can analyze emission data and recommend eco-friendly routing or packaging solutions. This not only aligns logistics operations with environmental regulations but also enhances brand reputation and customer trust.

Integrating AI into Your Logistics Ecosystem

Implementing AI successfully requires a structured approach. Businesses must identify key operational pain points and determine where AI can deliver the highest ROI.

Key steps include:

- Data readiness: Clean, high-quality data is essential for accurate AI predictions.

- Technology integration: Combine AI tools with existing ERP, TMS, or WMS systems.

- Scalable solutions: Start small (e.g., route optimization) and expand as results validate ROI.

- Continuous learning: AI models improve with time and data — enabling constant performance enhancement.

The Future of AI in Logistics: What’s Next?

The integration of AI into logistics is still evolving. Over the next decade, we can expect:

- Fully autonomous delivery fleets powered by AI and IoT

- Cognitive warehouses capable of self-management

- AI-driven predictive supply chains that self-optimize based on global trends

- Greater integration of AI with blockchain and robotics for transparency and automation

Businesses that adopt AI early will secure a competitive edge — not only reducing costs but also delivering superior customer experiences.

Conclusion: The Road Ahead for AI in Logistics

AI is no longer optional in logistics — it’s essential. From real-time delivery routing to predictive maintenance and automated warehouses, AI empowers logistics companies to work smarter, faster, and more sustainably.

Companies that embrace AI now will lead the way toward a future defined by efficiency, agility, and innovation. The logistics world is changing — and AI is driving the transformation.

FAQs

- How is AI used in logistics today?

AI powers route optimization, warehouse automation, demand forecasting, and predictive maintenance to improve efficiency and reduce costs. - What are the benefits of using AI in supply chains?

AI enhances decision-making, improves forecasting accuracy, minimizes downtime, and lowers operational costs. - How does AI route optimization work?

It uses live data such as traffic, weather, and delivery schedules to automatically generate the fastest and most efficient delivery paths. - Can small logistics companies afford AI?

Yes, scalable cloud-based AI platforms make it affordable for SMEs to start with solutions like route optimization or predictive maintenance. - What’s next for AI in logistics?

The future includes AI-powered automation, autonomous fleets, and predictive supply chains capable of real-time self-adjustment.